Home

ꄲ

High Pressure Reactor

ꄲ

Lab Reactor

ꄲ

High Pressure Lab Double Jacketed Butane Reactor Vessel

High Pressure Lab Double Jacketed Butane Reactor Vessel

A reactor can conduct a reaction under pressure inside its vessel, pressure reactor is a special application of a pressure vessel.

The pressure can be caused by the reaction itself or created by an external source, like hydrogen in catalytic transfer hydrogenation. High pressure reactors are used in reactions included but are not limited to Hydrogenation, Polymerization, Synthesis, Catalytic, Petrochemical and so on. They are also used to perform research such as Upstream, Biomass, Biopolymer, Zeolite, etc.

| Specifications and Technical Parameters | ||||

| Working Volume(L) | 0.1~1 | 1~10 | 10~25 | 25~50 |

| Working pressure(MPa) | Negative pressure -0.1~40 |

Negative pressure -0.1~40 |

Negative pressure -0.1~30 |

Negative pressure -0.1~30 |

| Working temperature(℃) | -196~500 | |||

| Stirring speed(r/min) | 0-1500 | |||

| Motor power(W) | 40~80 | 80~200 | 300~750 | 1100 |

| Heating power(KW) | 0.8~1 | 1~3 | 3~6 | 4~9 |

| Heating type | Electric heating, steam or water or thermal oil circulation, far infrared heating. | |||

| Charging type | Charging from above, discharging from below or above. | |||

| Shaft | Adopt self-lubricating wear-resistant sleeve, suitable for mixing various media. | |||

| Stirring type | Paddle type or anchor type or as per customer request | |||

| Seal type | Magnetic seal, packing seal. | |||

| Motor | 0.1~10L DC motor, 10~50L AC motor, both in explosion-proof type. | |||

| Reactor Main material | Contacting material inside kettle mainly use 0Cr18Ni9(304), 00Cr17Ni14Mo2(316L), 1Cr18Ni9Ti(321), 0Cr25Ni20(310) also can be produced by titanium(TA2), nickel, zirconium, hastelloy, etc, or lined with PTFE, PPL, PFA and Ni (Ni6) according to different requirements of reaction media. | |||

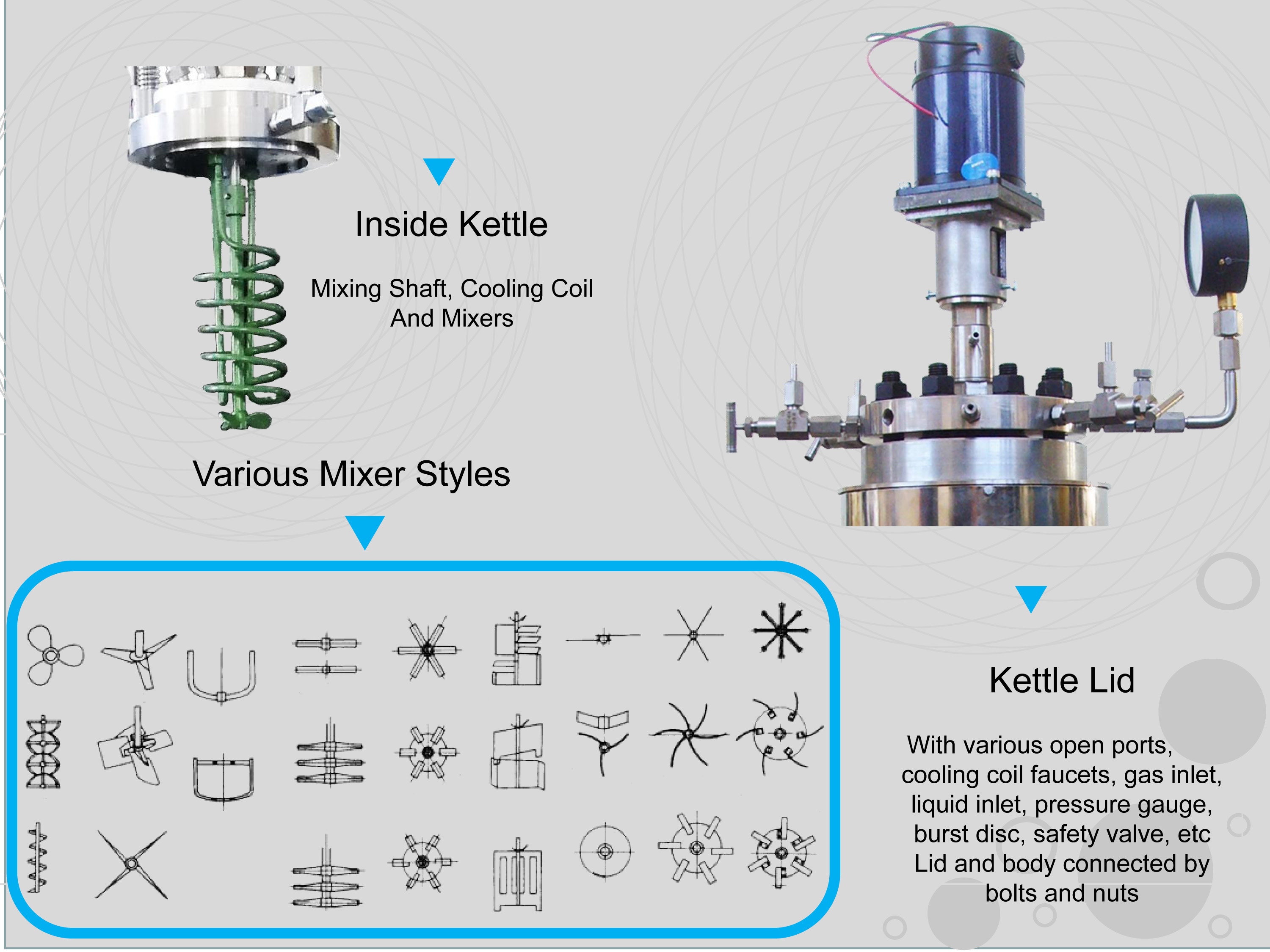

| Opening port of conventional kettle lid | Needle Valve on Gas Port and Liquid Port, Bottom Insert Tube for sampling or inlet use, Pipe Plug on Solid Charging Port, Platinum Resistance (PT100) on measuring and controlling Temperature Port, Pressure Gauge and Safety Device (Blasting Disc) on Security Blasting Port, and Inlet and Outlet of Cooling Coil inside the reactor with tap. | |||

| Controller Device | Equipped with automatic or programmed PID or PLC to achieve: Temperature display and control, accuracy ± 1 ℃; Program Control; Mixing Speed display and control; Pressure display and control; Level display and control; Flow display and control; Valve open/close control, etc. |

|||

Advantages

1. It can conduct a reaction above the boiling point of a solvent.

2. Closed vessel with static magnetic seal can prevent releasing toxic gas and explosions.

3. The pressure can reduce the reaction volume, less solvent is needed, including the liquid phase, and in turn increase concentration and collision frequency, and accelerate a reaction.

Tip: Increase in temperature can speed up the desired reaction, but also speed up the decomposition of reagents and starting materials. However, pressure can speed up the desired reaction and only impacts decomposition when it involves the release of a gas or a reaction with a gas in the vessel. When the desired reaction is accelerated, competing reactions are minimized. Pressure generally enables faster reactions with cleaner reaction profiles.

Application: chemical industry, medicine, food, biology, health, printing, dyeing, plastic, materials, and other fields.

The reactor lid and reactor body are connected by bolts and nuts on flanges, some times, quick open structure will be used for easy opening process.With water or gas circulation through cooling coil, temperature inside reactor kettle can be cool down quickly without opening kettle lid. Types of mixer styles available for various working medium according to different viscosity and property.